Extended Aeration

Extended aeration is a method of sewage treatment using modified activated sludge procedures. It is preferred for relatively small waste loads, where lower operating efficiency is offset by mechanical simplicity. Extended aeration agitates all incoming waste in the sludge from a single clarifier. The combined sludge starts with a higher concentration of inert solids than typical secondary sludge and the longer mixing time required for digestion of primary solids in addition to dissolved organics produces aged sludge requiring greater mixing energy input per unit of waste oxidized. Extended aeration is typically used in prefabricated “package plants” intended to minimize design costs for waste disposal from small communities, tourist facilities, or schools. In comparison to traditional activated sludge, longer mixing time with aged sludge offers a stable biological ecosystem better adapted for effectively treating waste load fluctuations from variable occupancy situations. Supplemental feeding with something like sugar is sometimes used to sustain sludge microbial populations during periods of low occupancy, but population response to variable food characteristics is unpredictable, and supplemental feeding increases waste sludge volumes. Sludge may be periodically removed by septic tank pumping trucks as sludge volume approaches storage capacity.

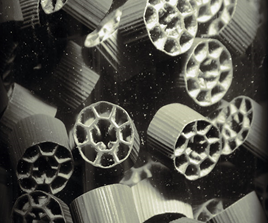

Moving Bed Biofilm Reactor

The Moving Bed Biofilm Reactor technology is a biological solution for wastewater treatment, based on a core understanding of microbiology and treatment processes. This simple and robust biological treatment process is suitable for specific wastewater treatment processes nitrogen reduction, high BOD/COD removal, including difficult industrial wastewater requirements. At the core of the technology, specially designed polyethylene biofilm carriers provide a large surface area for micro-organisms to grow on and perform specific biological treatment functions. Carriers are kept in suspension in the reactor either by the aeration system. Bacteria from the wastewater attach themselves to the floating carriers. The very compact configuration helps to achieve a highly active biomass concentration in the reactor and a low settling load in the downstream solids separation process. Biofilm wastewater treatment technologies are very robust, especially when compared to conventional technologies like activated sludge.

Advantages:-

- High tolerance to load variations (including suspended solids) and toxic shocks

- Low solids load on the clarifier

- Very compact configuration, able to fit in very small spaces

- High removal efficiencies for nitrogen, BOD and COD

- Stable process and easy to operate

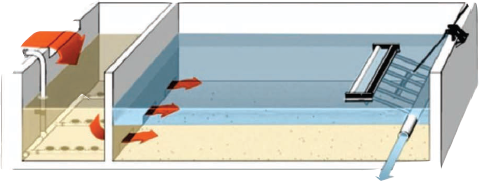

Sequential Batch Reactor

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches. Oxygen is bubbled through the mixture of wastewater and activated sludge to reduce the organic matter (measured as biochemical oxygen demand (BOD) and chemical oxygen demand (COD)). The treated effluent may be suitable for discharge to surface waters or possibly for use on land. There are five stages in the treatment process:-

- Fill

- React

- Settle

- Decant

- Idle

The inlet valve opens and the tank is being filled in, while mixing is provided by mechanical means (no air). This stage is also called the anoxic stage.

Aeration of the mixed liquor is performed during the second stage by the use of fixed or floating mechanical pumps or by transferring air into fine bubble diffusers fixed to the floor of the tank. No aeration or mixing is provided in the third stage and the settling of suspended solids starts. During the fourth stage, the outlet valve opens and the “clean” supernatant liquor exits the tank.

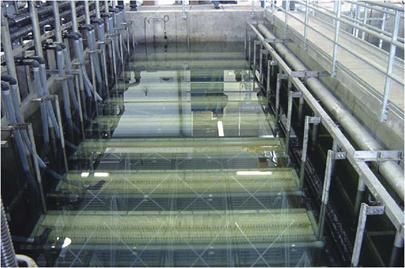

Membrane Bio-Reactor

Membrane bioreactor (MBR) is the combination of a membrane process like microfiltration or ultrafiltration with a suspended growth bioreactor and is now widely used for municipal and industrial wastewater treatment with plant sizes up to 80,000 population equivalent When used with domestic wastewater, MBR processes can produce effluent of high quality enough to be discharged to the coastal, surface or brackish waterways or to be reclaimed for urban irrigation. Other advantages of MBRs over conventional processes include small footprint, easy retrofit, and upgrade of old wastewater treatment plants. It is possible to operate MBR processes at higher mixed liquor suspended solids (MLSS) concentrations compared to conventional settlement separation systems, thus reducing the reactor volume to achieve the same loading rate. Two MBR configurations exist: internal/submerged, where the membranes are immersed in and integral to the biological reactor; and external/side stream, where membranes are a separate unit process requiring an intermediate pumping step. Membrane bioreactors can be used to reduce the footprint of an activated sludge sewage treatment system by removing some of the liquid components of the mixed liquor. This leaves a concentrated waste product that is then treated using the activated sludge process.